Teil 1: 5 Anzeichen dafür, dass Ihr Filament Feuchtigkeit aufgenommen hat

Filament sieht nicht immer „nass“ aus, aber diese Warnsignale zeigen Ihnen, dass es Zeit ist, es zu trocknen:

- Knisternde oder knallende Geräusche während der Extrusion (austretender Dampf).

- Oberflächenfehler: Raue Texturen, Blasen oder übermäßige Fadenbildung.

- Inkonsistente Extrusion: Filament sickert auch nach dem Stoppen des Extruders heraus.

- Schwache Drucke: Teile brechen leicht oder Schichten trennen sich unter Belastung.

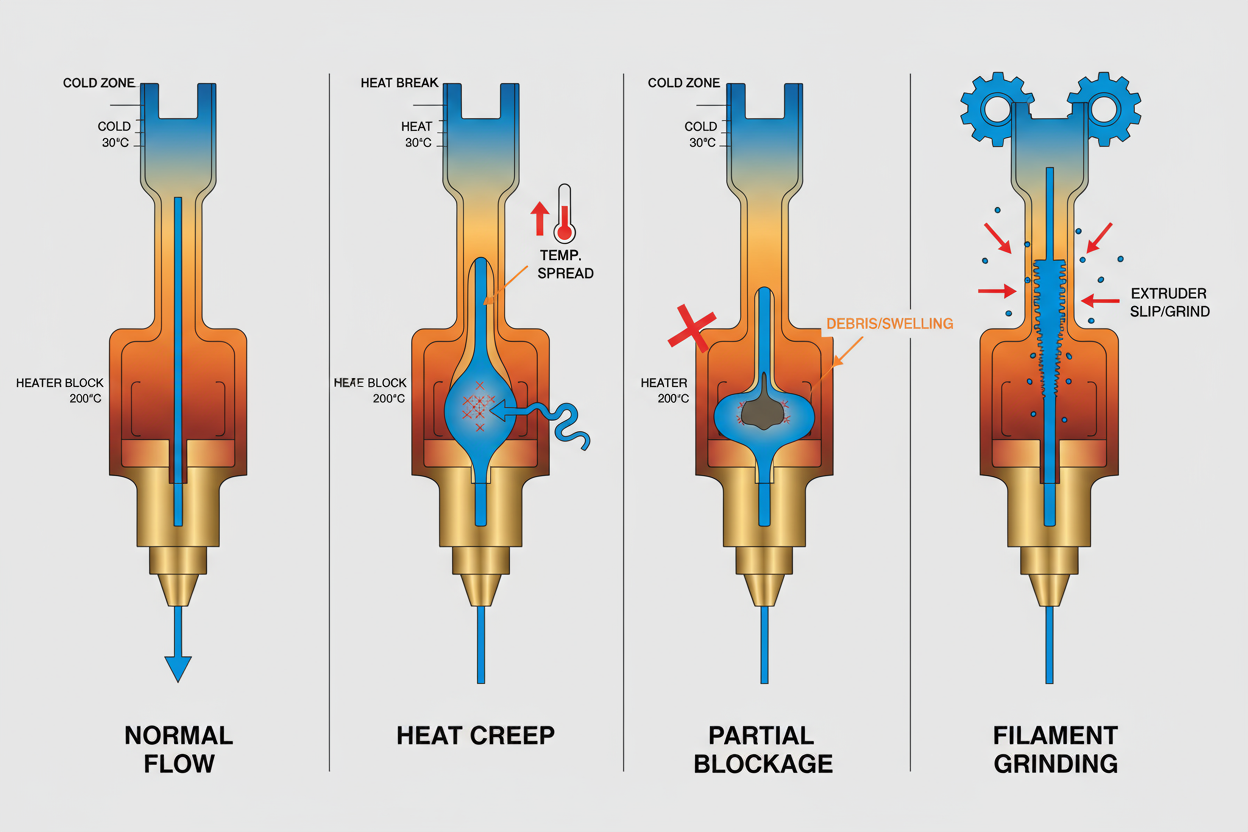

- Düsenverstopfungen: Verbrannte Rückstände durch Feuchtigkeitsverkohlung.

---

Teil 2: 3 effektive Methoden zum Trocknen von Filament

1. Verwenden Sie einen Filamenttrockner

Ein spezieller Filamenttrockner ist die sicherste und effizienteste Option. Achten Sie auf:

- Präzise Temperaturregelung (z. B. PLA: 104–122 °F / 40–50 °C; Nylon: 167–194 °F / 75–90 °C).

- Integrierter Luftstrom zur gleichmäßigen Wärmeverteilung.

- Versiegelte Lagermöglichkeit, um das Filament nach dem Trocknen trocken zu halten.

Schritte:

1. Spule in den Trockner legen und die materialspezifische Temperatur einstellen.

2. 4–6 Stunden erhitzen (8 Stunden bei hygroskopischen Materialien wie Nylon).

3. Nach dem Trocknen sofort in einen luftdichten Behälter umfüllen.

---

2. Ofentrocknen (für den Notfall)

Wichtig: Verwenden Sie immer ein Ofenthermometer, um ein Schmelzen des Filaments zu vermeiden!

- Temperaturrichtlinien:

- PLA: 40–50 °C (104–122 °F) für 4–6 Stunden.

- ABS: 149–167 °F (65–75 °C) für 4–6 Stunden.

- Nylon: 75–90 °C (167–194 °F) für 6–8 Stunden.

- Sicherheitstipps:

- Legen Sie die Spulen auf ein Backblech, entfernt von Heizelementen.

- Reinigen Sie den Ofen anschließend gründlich, um eine Kontamination der Lebensmittel zu vermeiden.

- Lüften Sie den Bereich – einige Materialien (wie ABS) geben starke Gerüche ab.

---

3. Dörrgerät-Methode

Eine budgetfreundliche Option, aber gehen Sie mit Vorsicht vor:

Temperatureinstellungen:

- PLA: ≤113°F (45°C) für 4-6 Stunden.

- Nylon: ≤176°F (80°C) für 6-8 Stunden.

- Änderungen:

- Entfernen Sie die Schalen, um die Spulen vertikal einzusetzen und so ein gleichmäßiges Trocknen zu gewährleisten.

- Verwenden Sie den Dörrapparat ausschließlich für Filamente – vermeiden Sie das Mischen mit Lebensmitteln.

---

Teil 3: Filament lagern: Trocken und sicher aufbewahren

Selbst getrocknetes Filament nimmt bei unsachgemäßer Lagerung wieder Feuchtigkeit auf. Beachten Sie diese Regeln:

1. Vakuumieren mit Trockenmitteln

- Verwenden Sie Hochleistungs-Vakuumbeutel und fügen Sie Silicagel-Päckchen hinzu (100 g pro Spule).

- Ersetzen Sie Trockenmittel, wenn sich ihre Farbe ändert (z. B. von Blau zu Rosa).

2. Kontrollieren Sie die Luftfeuchtigkeit

- Trocken lagern (idealerweise ≤30 % relative Luftfeuchtigkeit). Luftdichte Behälter mit Feuchtigkeitsindikatoren verwenden.

- Vermeiden Sie Keller, Badezimmer oder Garagen.

3. Minimieren Sie die Exposition

- Verwenden Sie beim Drucken für Open-Air-Setups einen Trockenbox-Feeder.

- Begrenzen Sie die Zeit im Freien auf 1–2 Stunden pro Sitzung.

4. Teile und herrsche

- Teilen Sie große Spulen in kleinere Portionen auf, um die häufige Belastung zu reduzieren.

---

Teil 4: FAQs

F: Meine Ausdrucke sind nach dem Trocknen immer noch schmutzig. Was ist los?

A: Das Filament ist möglicherweise nicht vollständig trocken. Verlängern Sie die Trocknungszeit oder überprüfen Sie die Düsentemperatur.

F: Kann ich zum Trocknen von Filament eine Mikrowelle verwenden?

A: Nein! Mikrowellen erhitzen ungleichmäßig und können den Heizfaden schmelzen oder Brände verursachen.

F: Wie lange hält getrocknetes Filament?

A: Vakuumversiegelt mit Trockenmittel: 6–12 Monate. Nach dem Öffnen innerhalb eines Monats verbrauchen.

---

Abschließende Tipps

- Beschriften Sie die Spulen mit Trocknungsdaten, um die Frische zu verfolgen.

- Investieren Sie in ein Hygrometer, um die Luftfeuchtigkeit im Lager zu überwachen.

– Teilen Sie Ihre Trocknungstricks in den Kommentaren unten!

Wenn Sie diese Techniken beherrschen, sparen Sie Zeit, reduzieren den Abfall und erzielen eine gleichbleibende Druckqualität. Viel Spaß beim Drucken!

---

Hinweis: Beachten Sie beim Umgang mit erhitzten Geräten immer die Richtlinien und Sicherheitsvorkehrungen des Herstellers.