(Free Spool Fix Model Included | AMS Filament Feeding Guide)

If you use a 3D printer with an AMS auto-feeding system, you’ve probably seen this message before:

“Nozzle Clogged”

Most users immediately assume the nozzle is dirty, the filament absorbed moisture, or the printing temperature is too low. That’s why many people start cleaning the hotend when a 3D printer nozzle clogged warning pops up.

But in this case, it was a completely different issue.

Recently, while printing with Lovoon matte tri-color 3D printer filament, I kept receiving a —even though the nozzle was perfectly fine.

The Nozzle Was Not Clogged–The Filament Simply Stopped Feeding

The print started perfectly.

About 30 minutes later, the printer reported:

“Nozzle Clogged”

I removed the filament, cleaned the nozzle, restarted the print…

Ten minutes later: same nozzle clogged error again.

So I watched the AMS closely.

And this time, I discovered the real cause of the so-called nozzle clogged but not clogged situation:

The paper spool had slightly deformed and slipped on the AMS rollers

Because the AMS rollers lost grip, the filament stopped feeding, and the machine thought nothing was extruding.

So the printer interpreted AMS filament not feeding as a nozzle clog.

In reality, there was no clog at all.

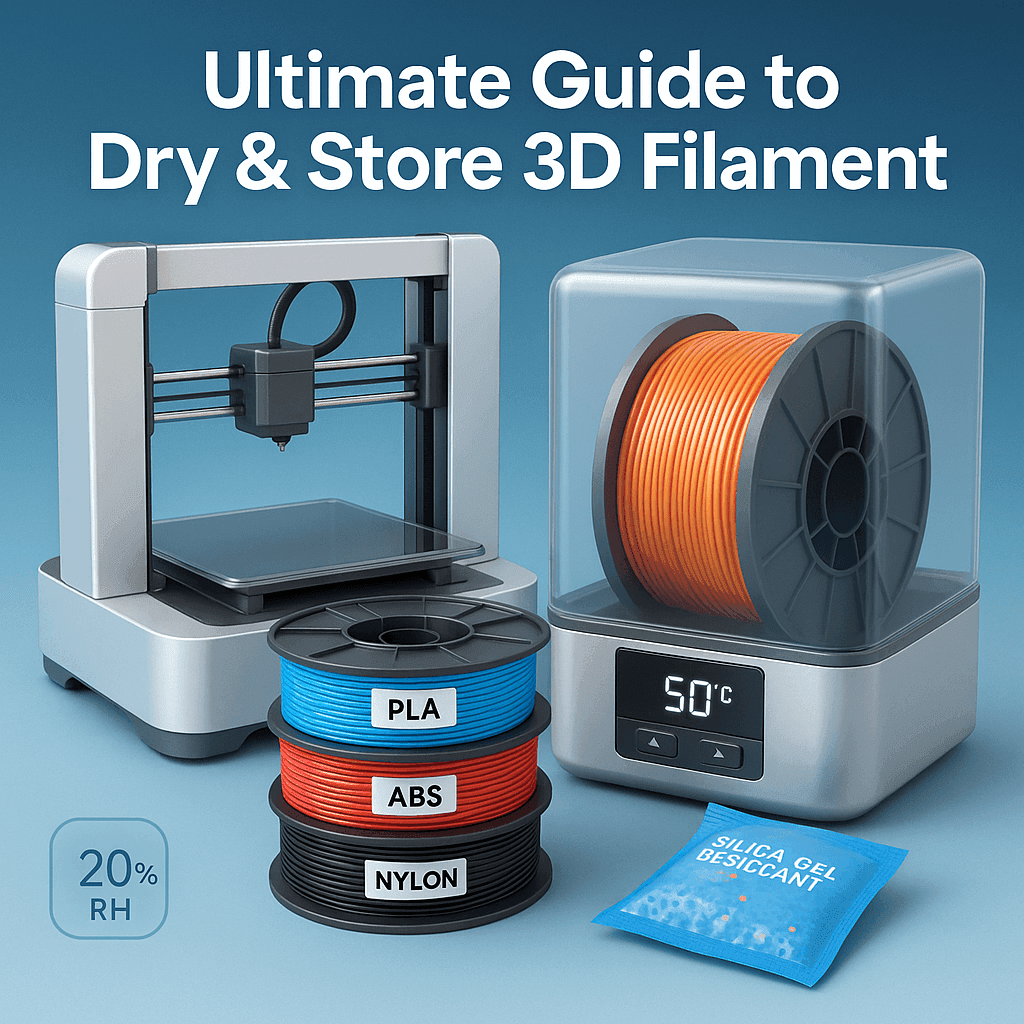

Why Paper Spools Can Cause Slipping

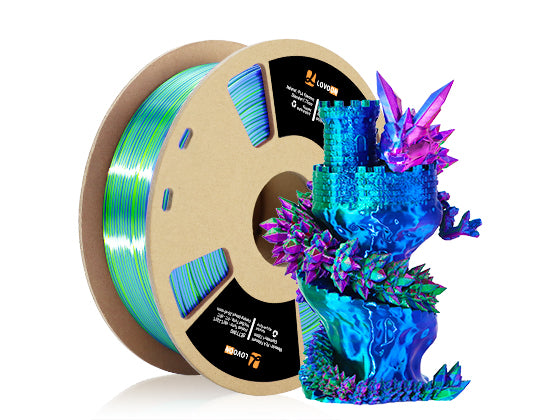

Lovoon uses eco-friendly, lightweight paper spools.

But under shipping pressure or humidity, the spool edges may soften or curve slightly.

When that happens:

AMS rollers lose friction

The filament stops advancing

The machine triggers nozzle clogged error

You waste time cleaning a nozzle that isn’t clogged

This is a common paper spool 3D printing problem, especially for AMS users.

Simple Fix: Print a Spool Clamp

To stop the slipping, I printed a small spool clamp 3D print designed for 20 mm paper-core spools.

✅ Holds spool shape

✅ Prevents slipping or deformation

✅ Restores smooth AMS filament feeding

✅ Works for mini spools or non-standard spool sizes

After installing the clamp, I printed overnight for 6 hours with zero issues.

If your spool diameter is different, just scale the model and reprint.

➡️ Free STL download: (insert link)

Link

Original concept by @Extreme, modified and dimension-optimized for paper spool performance.

If the link is broken, you can search for the author directly and adjust the size to 204mm to perfectly fit Lovoon's consumables tray.

Why Paper Spools Are Still Worth It

Some ask: “Why not just use plastic spools?”

Paper spools:

✔ Are fully recyclable

✔ Reduce plastic waste

✔ Lower shipping weight & carbon footprint

✔ Protect filament without hard-edge pressure

A tiny clamp solves compatibility issues while keeping everything environmentally friendly.

Is the Filament Causing Clogs? — No.

To confirm, I tested:

✔ Nozzle cleaning

✔ Higher printing temperature

✔ Multiple spool sizes

✔ Direct-feed printing without AMS

The filament printed perfectly every time.

The only failure happened when AMS spool slipping stopped filament feeding.

So if your 3D printer filament not feeding but your nozzle looks clean, start by checking spool grip—not tearing the printer apart.

Quick Troubleshooting for AMS Users

|

Issue |

Cause |

Fix |

|

Under-extrusion mid-print |

Spool slipping |

Use spool clamp |

|

AMS not reading small spools |

Diameter too small |

Scale clamp |

|

Nozzle clogged error but nozzle is clean |

Filament not feeding |

Check roller grip |

This is the easiest nozzle clogged error fix if you use paper spools.

If You’re New to Lovoon

If you like:

✔ Matte texture

✔ Multi-color / tri-color gradient effects

✔ Glow-in-the-dark prints

✔ Eco-friendly packaging

Lovoon’s paper-spool design works perfectly with AMS once the clamp is installed — and the printed model is free for anyone to download, even if you use other filaments.

Final takeaway

Next time you see a “nozzle clogged” warning but the nozzle looks clean, don’t panic—

you may simply be experiencing AMS filament not feeding due to spool slipping.

A 10-minute spool clamp 3D print can fix hours of wasted troubleshooting.